Home / All / Terminal Crimping Machine / Wire Stripping and Terminal Crimping Machine /

TR-1600 Upgraded Version of Automatic Wire Stripping and Terminal Crimping Machine

TR-1600 Upgraded Version of Automatic Wire Stripping and Terminal Crimping Machine

Detail Information

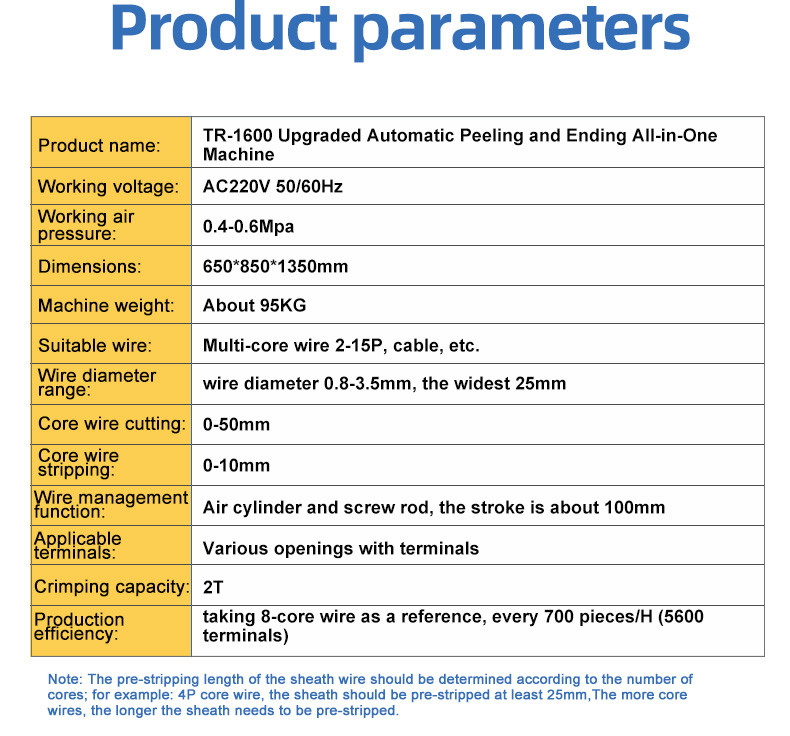

TR-1600 Upgraded Version of Automatic Wire Stripping and Terminal Crimping Machine

Working voltage:AC220V 50/60Hz

Working air pressure:0.4-0.6Mpa

Dimensions:650*850*1350mm

Machine weight:About 95KG

Suitable wire:Multi-core wire 2-15P,cable, etc.

Wire diameter range:wire diameter 0.8-3.5mm, the widest 25mm

Core wire cutting:0-50mm

Core wire stripping:0-10mm

Wire management function:Air cylinder and screw rod, the stroke is about 100mm

Applicable terminals:Various openings with terminals

Crimping capacity:2T

Production Efficiency:taking 8-core wire as a reference, every 700 pieces/H (5600terminals)

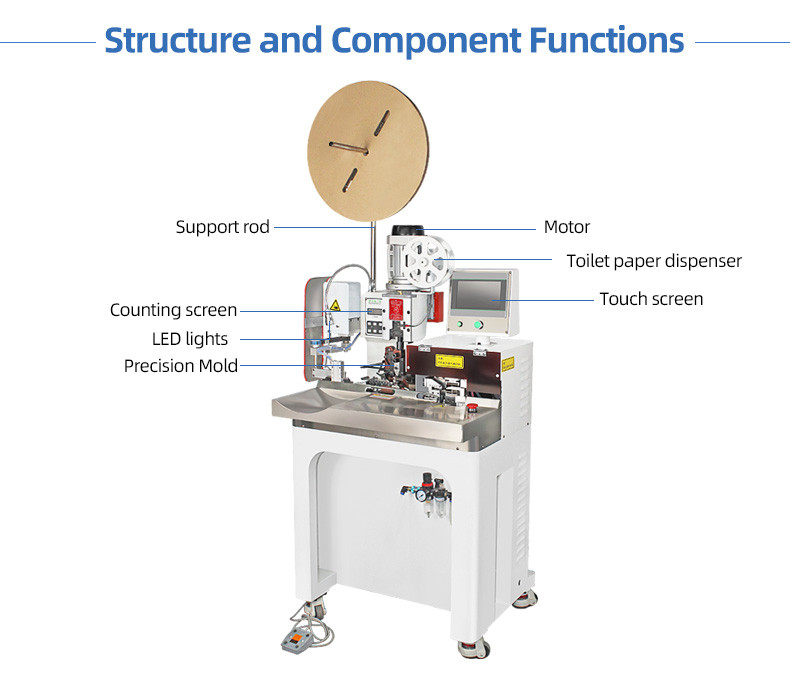

All-in-one machine for automatic cable management,stripping, and end cutting

Note: The pre-stripping length of the sheath wire should be determined according to the number ofcores; for example: 4P core wire, the sheath should be pre-stripped at least 25mm,The more corewires, the longer the sheath needs to be pre-stripped.

Note: The pre-stripping length of the sheath wire should be determined according to the number ofcores; for example: 4P core wire, the sheath should be pre-stripped at least 25mm,The more corewires, the longer the sheath needs to be pre-stripped.

Related Products

Review

- Loading...

Please send your message to us

- *Name

- *Tel

- *Title

- *Content

Categories

- Terminal Crimping Machine

- Fully Automatic Terminal Crimping Machine

- Inserting Tube Terminal Crimping Machine

- Plastic Shell Terminal Crimping Machine

- Semi-automatic Bulk Terminal Crimping Machine

- Wire Stripping and Terminal Crimping Machine

- Fully Automatic Sheathed Wire Terminal Crimping Machine

- New Energy Servo Terminal Crimping Machine

- Semi-automatic Mute Terminal Crimping Machine

- Inserting Waterproof Plug Terminal Crimping Machine

- Sheathed wire Terminal Crimping Machine

- Dipping Tin Terminal Crimping Machine

- Cable Terminal Crimping Machine

- Semi-auto Copper Strip Crimping Machine

- Cable/Wire Cutting and Stripping Machine

- Cutting Machine

- Tape Wrapping Machine

- Cable Winding and Tying Machine

- Inserting Tube Machine

- Connector Nut Screwing Machine

- Others

subscription

Please send your message to us

- *Name

- *Tel

- *Title

- *Content