Home / All / Terminal Crimping Machine / Dipping Tin Terminal Crimping Machine /

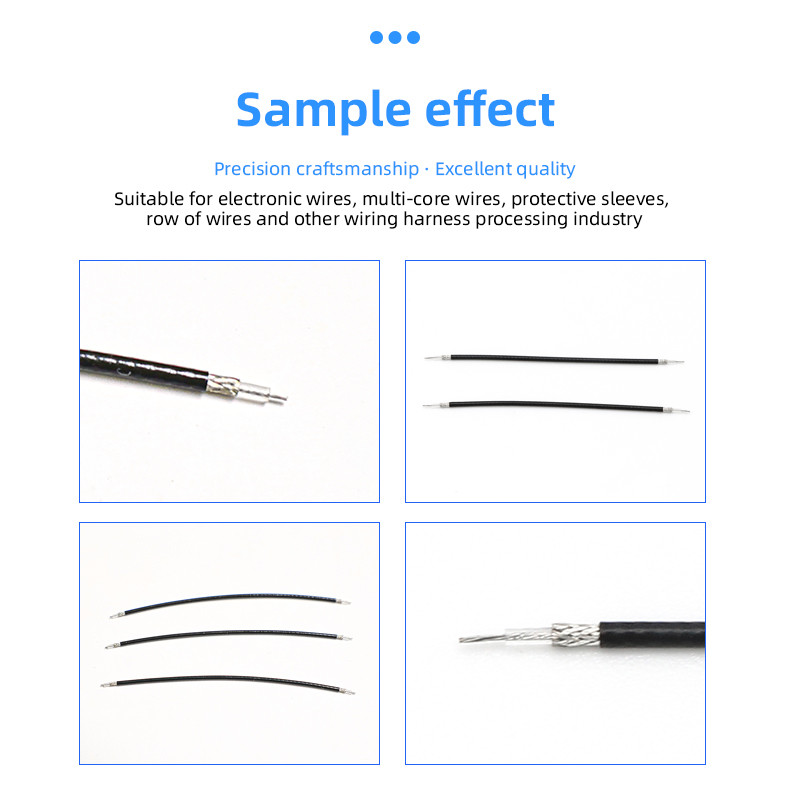

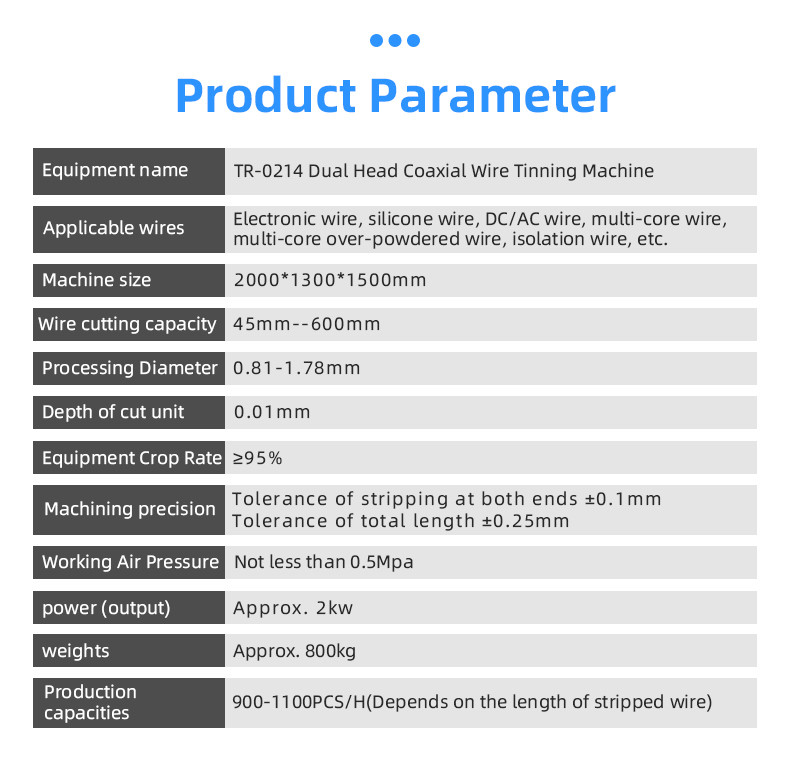

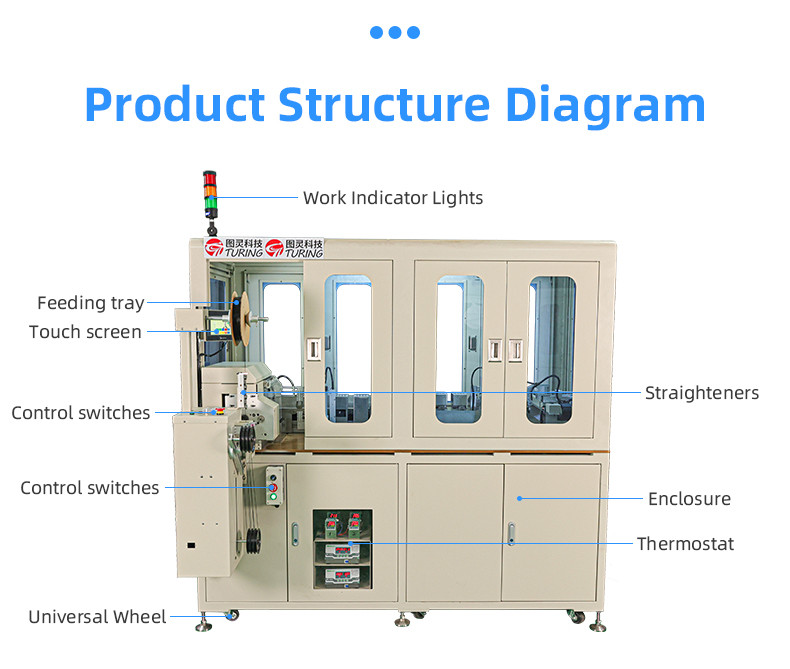

TR-0214 Double-head coaxial line tin dipping machine

TR-0214 Double-head coaxial line tin dipping machine

Detail Information

TR-0214 Double-head coaxial line tin dipping machine

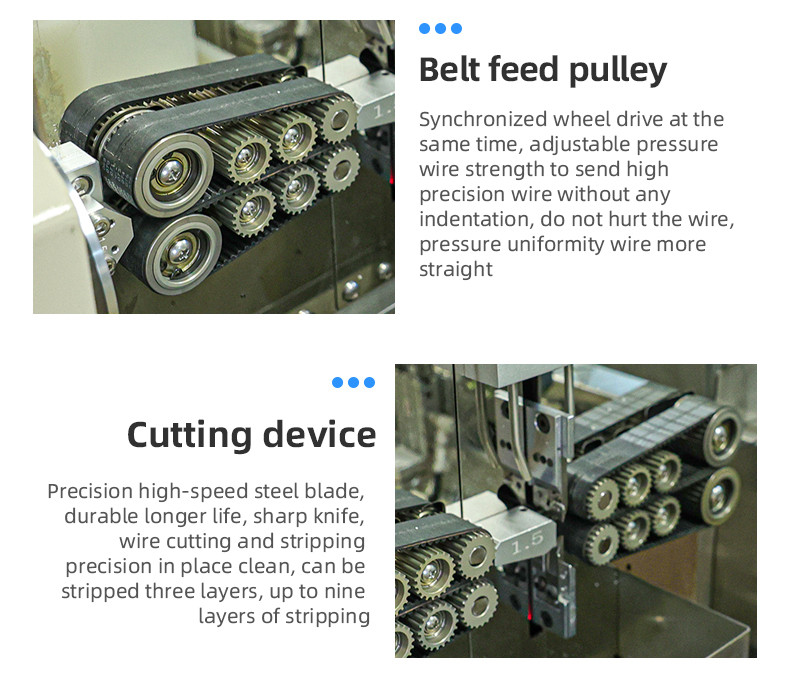

Cutting device

Precision high-speed steel bladedurable longer life, sharp knife,wire cutting and strippingprecision in place clean,can bestripped three layers,up to ninelayers of stripping

Belt feed pulley

Synchronized wheel drive at thesame time, adjustable pressurewire strength to send highprecision wire without anyindentation, do not hurt the wirepressure uniformity wire morestraight

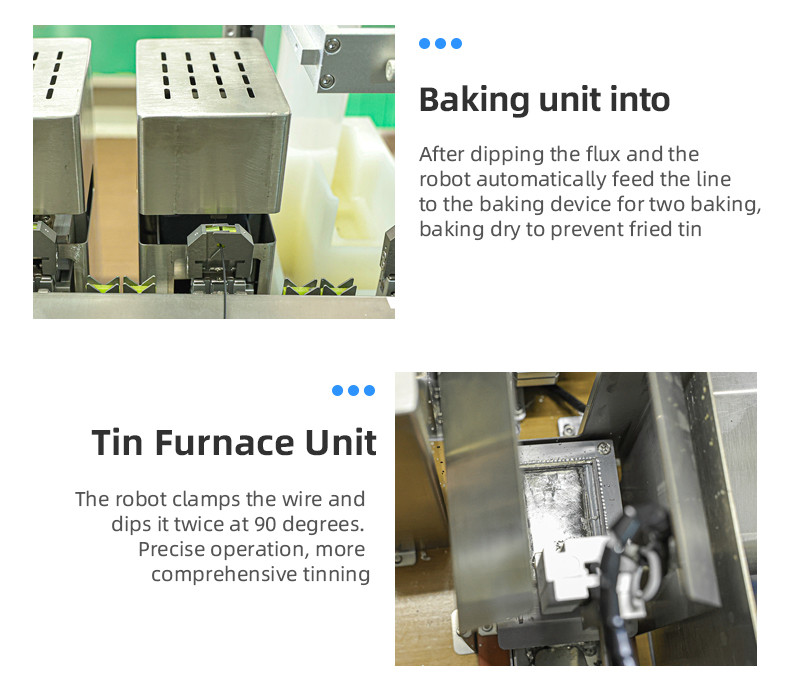

Tin Furnace Unit

The robot clamps the wire anddips it twice at 90 degreesPrecise operation,morecomprehensive tinning

Baking unit into

After dipping the flux and the

robot automatically feed the lineto the baking device for two baking,baking dry to prevent fried tinning

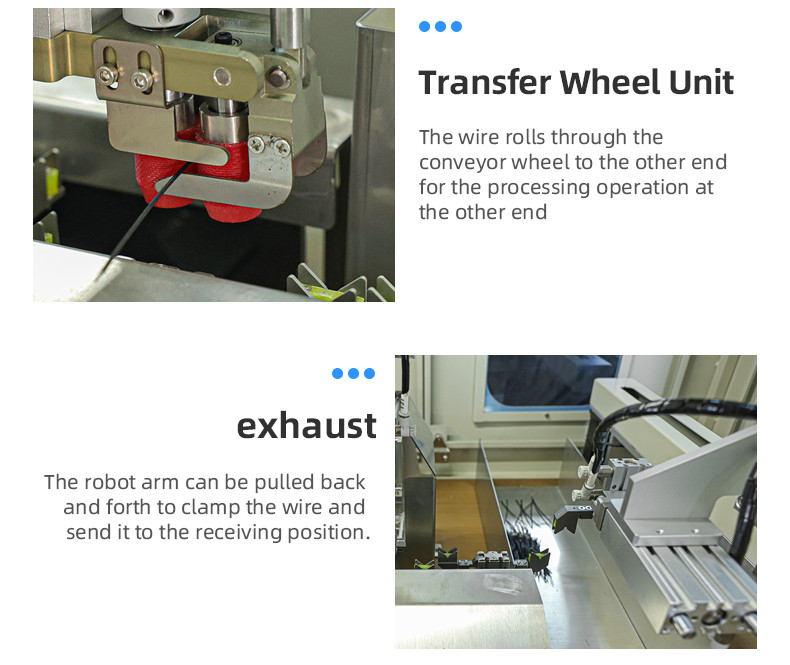

exhaust

The robot arm can be pulled backand forth to clamp the wire andsend it to the receiving position

Transfer wheel Unit

The wire rolls through the

conveyor wheel to the other endfor the processing operation atthe other end

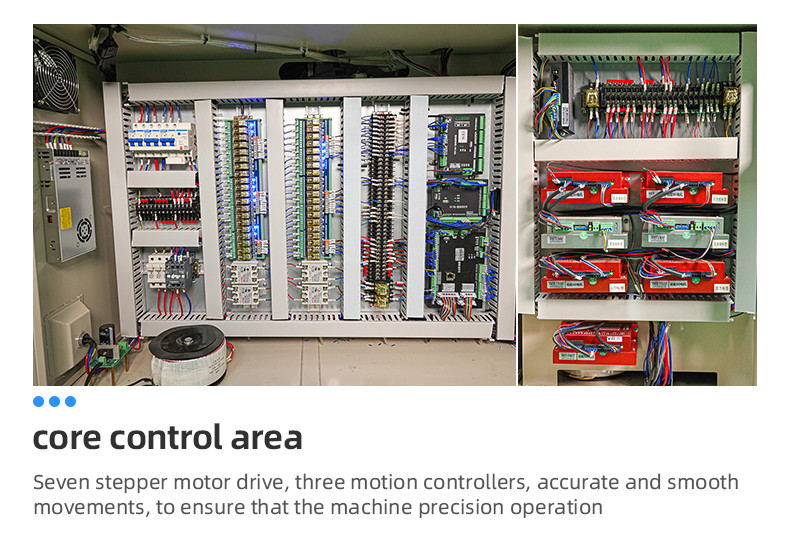

core control area

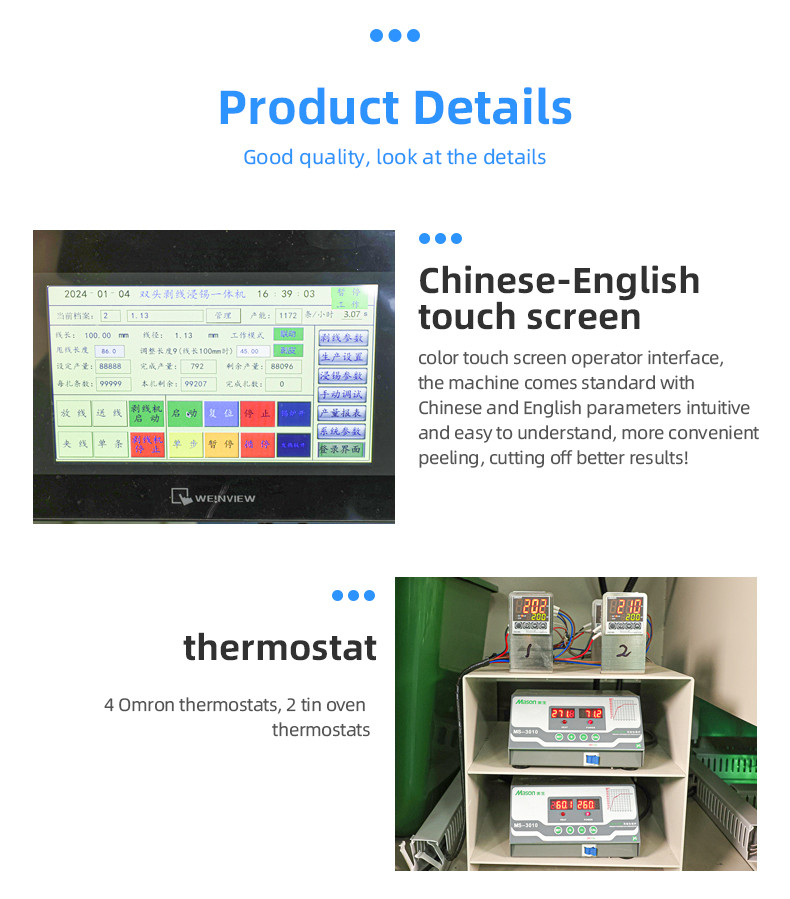

Seven stepper motor drive, three motion controllers, accurate and smoothmovements,to ensure that the machine precision operation

Related Products

Review

- Loading...

Please send your message to us

- *Name

- *Tel

- *Title

- *Content

Categories

- Terminal Crimping Machine

- Fully Automatic Terminal Crimping Machine

- Inserting Tube Terminal Crimping Machine

- Plastic Shell Terminal Crimping Machine

- Semi-automatic Bulk Terminal Crimping Machine

- Wire Stripping and Terminal Crimping Machine

- Fully Automatic Sheathed Wire Terminal Crimping Machine

- New Energy Servo Terminal Crimping Machine

- Semi-automatic Mute Terminal Crimping Machine

- Inserting Waterproof Plug Terminal Crimping Machine

- Sheathed wire Terminal Crimping Machine

- Dipping Tin Terminal Crimping Machine

- Cable Terminal Crimping Machine

- Semi-auto Copper Strip Crimping Machine

- Cable/Wire Cutting and Stripping Machine

- Cutting Machine

- Tape Wrapping Machine

- Cable Winding and Tying Machine

- Inserting Tube Machine

- Connector Nut Screwing Machine

- Others

subscription

Please send your message to us

- *Name

- *Tel

- *Title

- *Content