Home / All / Cable/Wire Cutting and Stripping Machine / Computer Wire Stripping Machine /

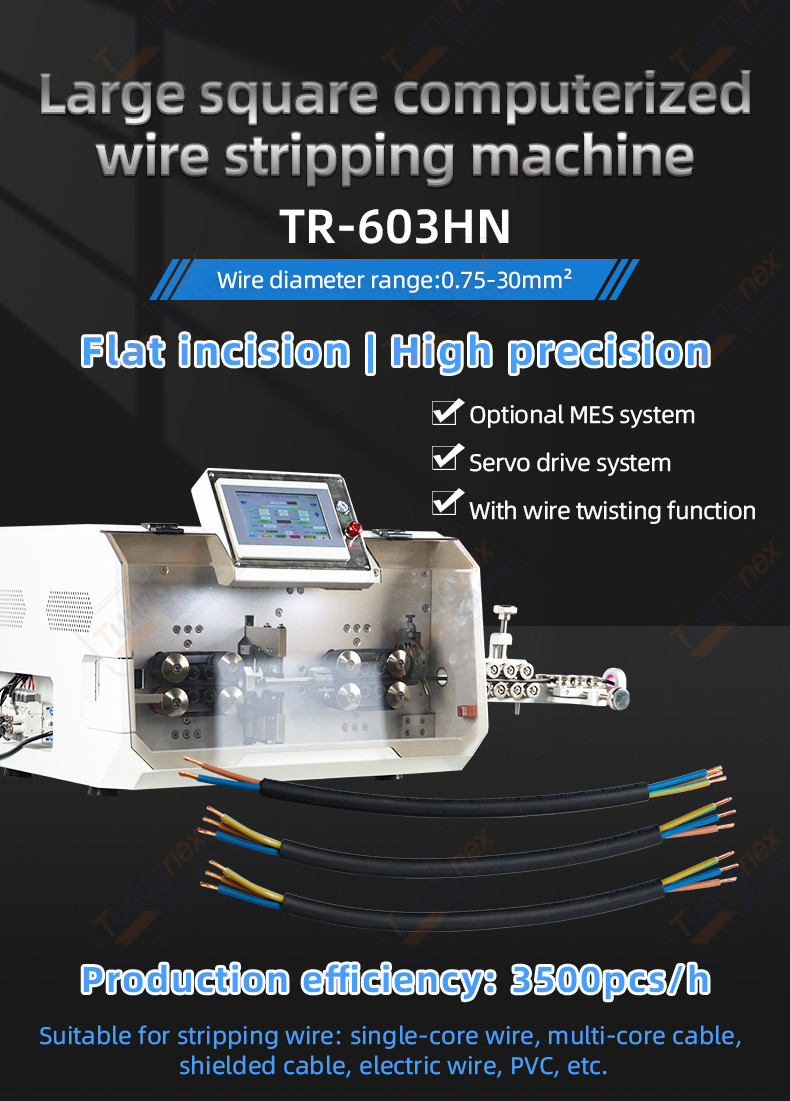

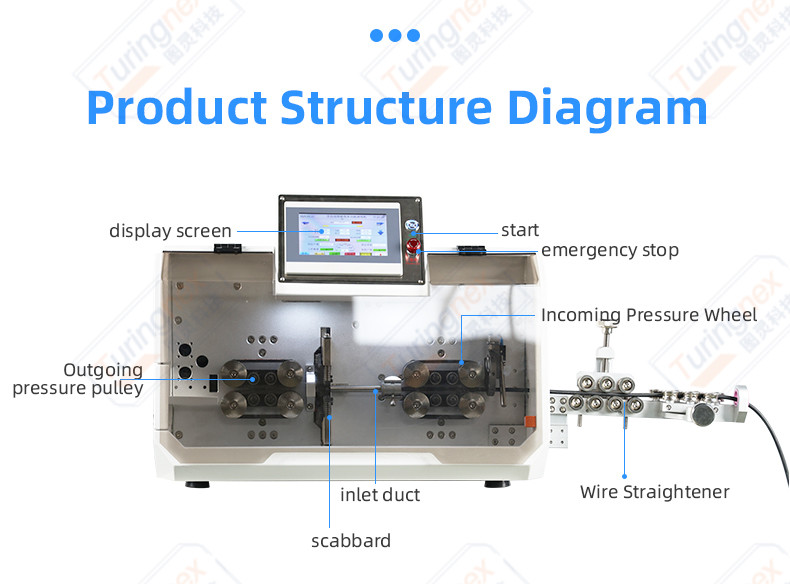

TR-603HN Large Square Computerized Wire Stripping Machine

TR-603HN Large Square Computerized Wire Stripping Machine

Detail Information

TR-603HN Large Square Computerized Wire Stripping Machine

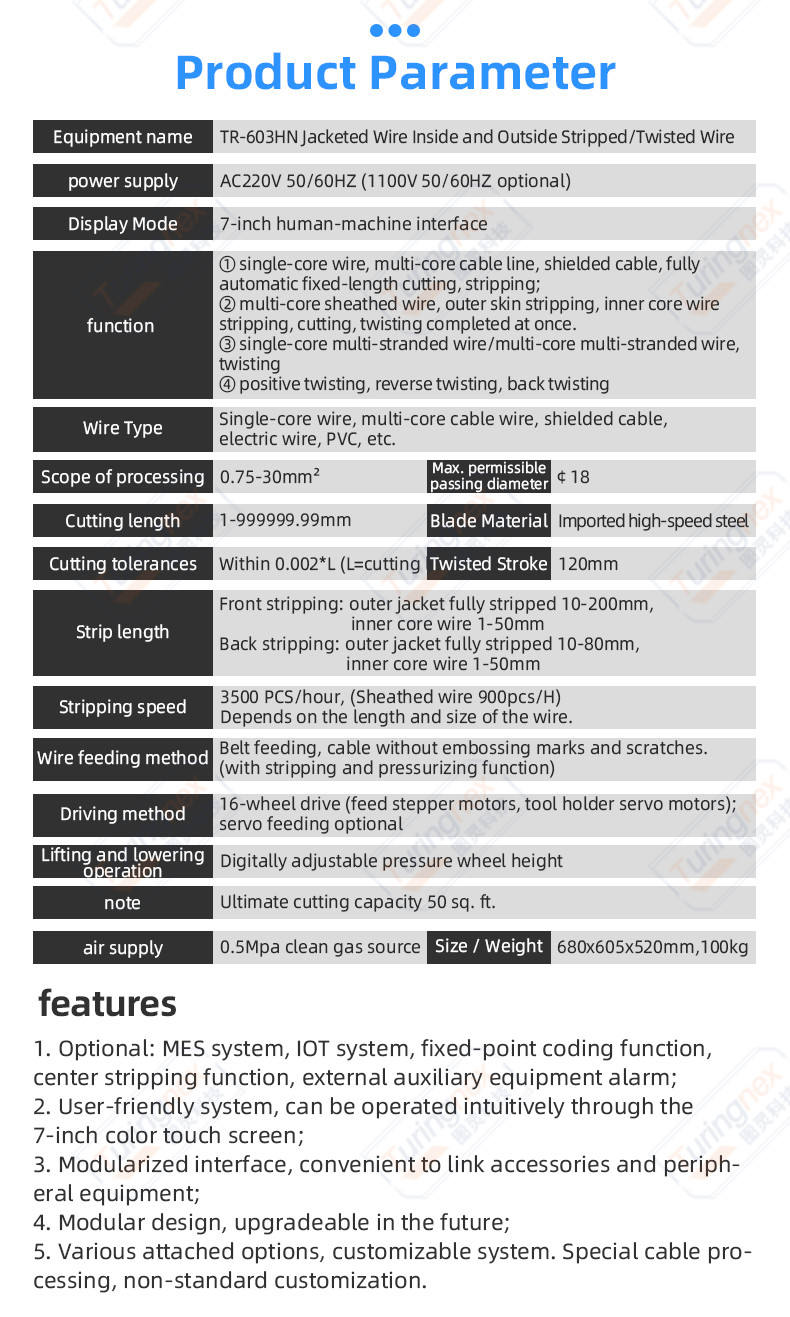

power supply:AC220V 50/60HZ (1100V 50/60HZ optional)

Display Mode:7-inch human-machine interface

Size / Weight:680x605x520mm,100kg

function :① single-core wire, multi-core cable line, shielded cable, fully automatic fixed-length cutting, stripping;

② multi-core sheathed wire, outer skin stripping, inner core wire stripping, cutting, twisting completed at once.

③ single-core multi-stranded wire/multi-core multi-stranded wire, twisting

④ positive twisting, reverse twisting, back twisting

Wire Type:Single-core wire, multi-core cable wire, shielded cable,

electric wire, PVC, etc.

Scope of processing:0.75-30mm²

Max. permissible passing diameter:¢18

Cutting length:1-999999.99mm

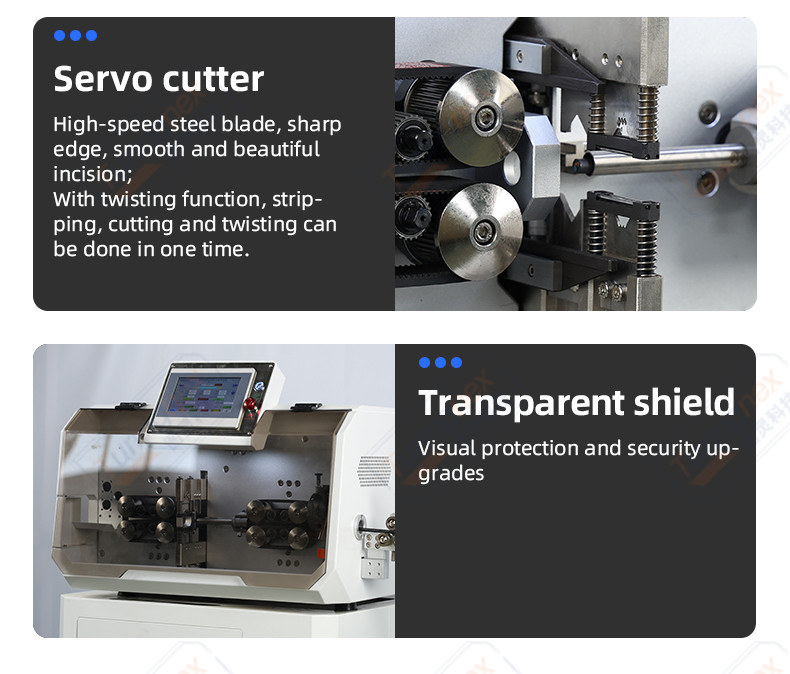

Blade Material:Imported high-speed steel

Cutting tolerances:Within 0.002*L (L=cutting length)

Twisted Wire Stroke:120mm

Strip length:Front stripping: outer jacket fully stripped 10-200mm, inner core wire 1-50mm;

Back stripping: outer jacket fully stripped 10-80mm, inner core wire 1-50mm

Stripping speed:3500 PCS/hour, (Sheathed wire 900pcs/H) Depends on the length and size of the wire.

Wire feeding method:Belt feeding, cable without embossing marks and scratches.

(with stripping and pressurizing function)

Driving method:16-wheel drive (feed stepper motors, tool holder servo motors);

servo feeding

optional

Lifting and lowering operation:Digitally adjustable pressure wheel height

note:Ultimate cutting capacity 50 sq. ft.

air supply:0.5Mpa clean gas source

features

1. Optional: MES system, IOT system, fixed-point coding function, center stripping function, external auxiliary equipment alarm;

2. User-friendly system, can be operated intuitively through the 7-inch color touch screen;

3. Modularized interface, convenient to link accessories and peripheral equipment;

4. Modular design, upgradeable in the future;

5. Various attached options, customizable system. Special cable processing, non-standard customization.

Related Products

Review

- Loading...

Please send your message to us

- *Name

- *Tel

- *Title

- *Content

Categories

- Terminal Crimping Machine

- Fully Automatic Terminal Crimping Machine

- Inserting Tube Terminal Crimping Machine

- Plastic Shell Terminal Crimping Machine

- Semi-automatic Bulk Terminal Crimping Machine

- Wire Stripping and Terminal Crimping Machine

- Fully Automatic Sheathed Wire Terminal Crimping Machine

- New Energy Servo Terminal Crimping Machine

- Semi-automatic Mute Terminal Crimping Machine

- Inserting Waterproof Plug Terminal Crimping Machine

- Sheathed wire Terminal Crimping Machine

- Dipping Tin Terminal Crimping Machine

- Cable Terminal Crimping Machine

- Semi-auto Copper Strip Crimping Machine

- Fully Automatic Copper Tape Machine

- Cable/Wire Cutting and Stripping Machine

- Cutting Machine

- Tape Wrapping Machine

- Cable Winding and Tying Machine

- Inserting Tube Machine and Heat Shrink Tube Baking Machine

- Connector Nut Screwing Machine

- Others

- Labeling Maching

- Parts for Terminal Crimping Machine and Wire Cutting and Stripping Machine

- Caster Assembly Machine

- New Energy Battery Pack Assembly Line

- Foaming Machine

- Dispensing and backing machine

- Wire threading braided mesh machine and plastic tube machine

- Dental Floss Making Machine

- Cable Cutting Machine

- Heat Shrink Baking Machine

- Pay-off rack

- Copper stripping machine

subscription

Please send your message to us

- *Name

- *Tel

- *Title

- *Content